Supervisor: prof. Dario De Domenico

European Research Council (ERC):

PE8_3

Laboratory Location:

Block A, Floor 0 and Floor 1, Room 001

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory is equipped to perform mechanical characterization tests on the main materials used in civil engineering (reinforced concrete, steel, masonry) in compliance with industry standards. The laboratory also conducts research and development to design and certify new materials, innovative testing protocols, and unconventional construction systems as part of research projects and scientific conventions. The main scientific-disciplinary sectors involved are CEAR-07/A (Construction Techniques) and CEAR-06/A (Construction Science).

Main activities:

Mechanical characterization tests on:

hardened concrete (specimen preparation, mechanical cutting and grinding, curing in a temperature-controlled tank, compression, flexural, and tensile tests on specimens); fresh concrete (mix design and optimal grain size selection, sieving and packaging of concrete specimens); cement and mortar (porosity, bulk density, heat of hydration); ordinary and prestressed reinforced concrete steel and tests on sections and metal structural elements (tensile, impact, bending, and straightening of bars); bricks and stone materials (compression, determination of density).

Sample collection and on-site testing of reinforced concrete, steel, and masonry structures (core drilling, carbonation testing, sclerometric and ultrasonic testing, floor load testing, pile and micropile testing, sonic testing, pull-out testing, endoscopies, flat jacks, bar extraction, pachometric testing, sheet metal hardness testing).

Main equipment:

High-stability press, 0-5000 kN, 0-600 kN, and 0-300 kN ranges; compression frame, 0-4000 kN range; compression frame, 0-3000 kN range; two-column electromechanical universal test machine, 0-600 kN range, equipped with a class 0.5 electronic strain gauge; four-column electromechanical universal test machine, 0-1200 kN range, equipped with a class 0.5 electronic strain gauge; flexural frame with one- and two-point concentrated load system, 0-100 kN range; two curing tanks with temperature controller and timer, maximum temperature 100°C; core drill; hammer; ultrasonic test data acquisition system; four tanks for load tests on floors Seven centesimal displacement transducers with support stands; circular saw, flat jacks with hydraulic system and displacement transducers; electronic scale with a full scale of 30 kg.

Contact: dario.dedomenico@unime.it

Supervisor: prof. Giuseppe Ricciardi

European Research Council (ERC):

PE8

Laboratory Location:

Block A, Floor 0, Room 1

Laboratory Type:

Research and Services

Laboratory Brief Description:

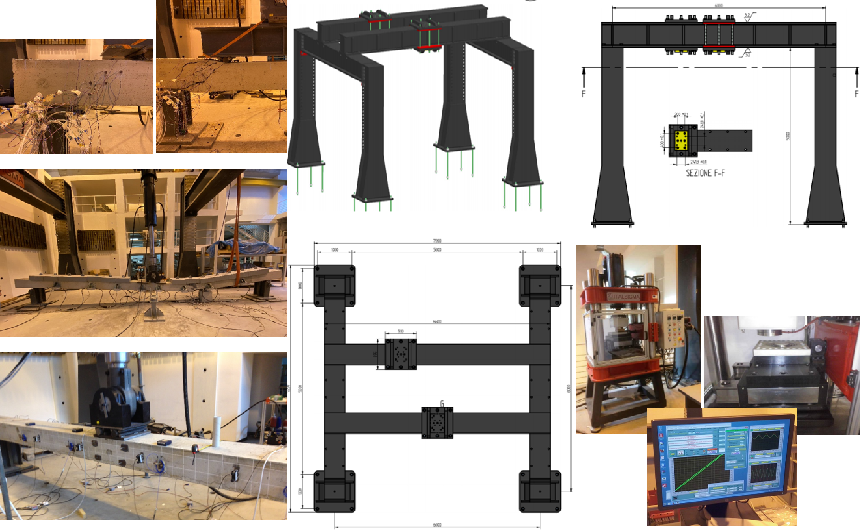

This section of the Structural Laboratory is dedicated to the design and execution of static and pseudo-dynamic tests on reinforced concrete, steelwork, and masonry structural elements.

A division dedicated to the experimental determination of the friction coefficient of sliding surfaces of seismic devices (UNI EN 1337-2) has also been recently established.

Main Activities:

The modularity of the test setup ensures ductility, allowing for different load configurations for up to six force application points.

The test environment and test execution method, in agreement with the client, are specifically designed for: i) the experimental characterization of prototype structural elements and/or structural systems, ii) or even to verify acceptability requirements and compliance with performance requirements stated during the design phase.

Finally, the updated equipment allows for short- and long-term friction tests to be performed on both hollow and recessed PTFE sheet specimens and on CM1 and CM2 composite material specimens, in compliance with UNI EN 1337-2.

Main instrumentation:

The test environment's geometric and mechanical flexibility relies on the following components:

One modular portal with an overall footprint of 6x6x5 m, attached to the reinforced concrete plate. of deck, two steel plates for connecting the actuators to the existing reinforced concrete retaining wall, two servo-hydraulic actuators with a nominal capacity of 1 MN and a stroke of ±375 mm, two servo-hydraulic actuators with a nominal capacity of 250 kN and a stroke of ±375 mm, two servo-hydraulic actuators with a nominal capacity of 500 kN and a stroke of ±375 mm, a dedicated hydraulic power unit for cylinder movement, complete with electronic control unit and management software application, a set of accelerometer sensors, strain gauges, and LVDT (Linear Variable Differential Transformers) transducers for monitoring significant physical parameters during the test; a set for monitoring deformation using optical deformation sensors; and a set for monitoring with Digital Image Correlation (DIC) with a single camera.

Finally, the dedicated equipment for short- and long-term friction tests, in compliance with UNI EN 1337-2, consists of:

One vertical-axis hydraulic actuator capable of applying a maximum force of 500 kN, stroke ±100 mm; One horizontal-axis hydraulic actuator capable of applying a maximum force of 100 kN, stroke ±100 mm; Two roller slides complete with rails; One climatic chamber, temperature range +50°/-50°C (under construction).

Contact: gricciardi@unime.it

Supervisor: prof. Gaetano Bosurgi

European Research Council (ERC):

PE8

Laboratory Location:

Block D, Floor 0, Room 002

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

Civil engineering projects are the result of significant theoretical knowledge, which only experimentally validates their effectiveness. Indeed, no technique or implementation method has not been adequately supported by direct experience on real or reproduced models, ensuring a level of reliability comparable to real-world cases. Theory and experimentation have therefore developed in parallel, and this process is ongoing, constantly seeking new technologies for the creation of high-performance and durable structures.

The objectives of experimentation in the civil engineering sector concern not only technologies but, above all, materials—that is, the precise understanding of the foundations of each project. The effectiveness, functionality, and durability of a structure are, in fact, closely related to its performance.

This highlights the highly strategic role played by a facility dedicated to the characterization, acceptance, and testing of all the materials and components that comprise a more complex structure.

These are the objectives of the Road Infrastructure Laboratory of the Department of Engineering.

It is a highly technologically innovative facility that also includes a mobile facility (Mobile Laboratory) for on-site testing.

The laboratory's research objectives cover the following topics:

mix design and performance characterization of materials for road, rail, and airport superstructures; analysis of the fatigue behavior and permanent deformation accumulation of bituminous mixtures; control and monitoring of the functional and structural characteristics of road and airport superstructures;

The laboratory also performs contract work.

Main activities:

Bitumen testing: Penetration Index (CNR 24/1971 EN 1426, ASTM D5, AASHTO T 49). Ring-ball softening point (CNR 35/1973, EN 1427, ASTM D36, AASHTO T 53). Fraass breaking point (43/1974, EN 12593); Testing of unbound soils and mixtures: Grain size analysis and Atterberg limits (CNR 10006/1963). Soil Density Gauge equipment for in-situ density control of unbound mixtures; Marshall bituminous mix design (EN 12697-34, ASTM D1559, BS 598, NF P98-251, CNR 30/1973). Indirect traction (CNR n° 134/1991, EN 12390-6, EN 1338, ASTM C496). Dynamic press gyratory compactor (UNI EN 12697-10, 12697-31; AASHTO T312); Rutting tests (accumulation of permanent deformations) on bituminous conglomerate plates; Aging and rheological tests on bitumen (PAV and BBR); On-site quality control of bituminous conglomerates and pavements. Skid Tester adhesion coefficient (CNR 105/1985, EN 1097-8, ASTM E103); Macroroughness and Longitudinal Irregularity Index (IRI) of the road profile (laser profilometer); Bearing capacity measurements with HWD instrumentation; On-site hot density control of bituminous mixtures; Adhesion measurements of road surfaces using ViaFriction equipment; Territorial surveys with Mobile Mapping instrumentation; Surface degradation surveys roads; Surface and medium-deep substrate surveys using GPR technology.

Main equipment:

HWD (Heavy Weight Deflectometer) equipment for non-destructive testing of the bearing capacity of multilayer systems (road, airport, and railway superstructures) with processing of the corresponding dynamic elastic moduli. ViaFriction equipment for measuring the coefficient of adhesion of road surfaces in both road and airport environments. HRDU (High Response Dynamic Unit) equipment for characterizing the structural performance of bituminous mixtures (fatigue tests, static and dynamic creep tests, dynamic resilient moduli, dynamic indirect tensile tests). Laser profilometer for measuring the regularity and texture of road surfaces. GEORADAR for assessing the thickness of road pavement layers and identifying any underground utilities. MOBILE MAPPING SYSTEM for the complete survey of road infrastructure and the environmental context in the form of point clouds and georeferenced images. PQI for measuring the in-situ hot density of bitumen-bonded layers of road pavements. Airports SDG for in-situ soil density measurement HiPross STRIPMASTER for measuring the retroreflectance of horizontal road and airport pavement markings ROLLER COMPACTOR for compacting bituminous concrete tiles of variable thickness WHEEL TRACKING for measuring the rutting resistance of bituminous concrete tiles MARSHALL PRESS AND COMPACTOR for studying the mechanical and volumetric properties of bituminous concrete specimens and assessing the optimal bitumen percentage GYRATORY COMPACTOR for studying the mix design of bituminous mixtures and assessing the density and other volumetric parameters of cylindrical specimens SKID TESTER for measuring the adhesion coefficient of paved surfaces in-situ PAV and BBR for the rheological study of bitumen, particularly regarding the characterization of bitumen's resistance to aging and its rigidity and relaxation properties at low temperatures.

Instrumentation for:

Penetration Index (CNR 24/1971 EN 1426, ASTM D5, AASHTO T 49). Ball-Ring Softening Point (CNR 35/1973, EN 1427, ASTM D36, AASHTO T 53). Fraass Breaking Point (43/1974, EN 12593); Atterberg Limits (CNR 10006/1963).

Contact: gbosurgi@unime.it

Supervisor: prof. Carla Faraci

European Research Council (ERC):

PE8_5 PE10_8 PE10_17

Laboratory Location:

Block A, Ground Floor, Rooms 3 and 4;

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The Hydraulics and Hydraulic Constructions Laboratory (LICI) is equipped to conduct research and provide services to the local community in the field of coastal and river hydromorphodynamics.

Main Activities:

The main activities addressed through physical model experiments concern the interaction between waves and port structures or coastal defenses; the estimation of hydraulic risk and coastal erosion; the nourishment and management of underwater quarries, the diffusion of pollutants, the transport of plastics, etc. The laboratory's activities result in scientific publications such as publications in national and international conference proceedings, indexed journals, and internal reports. Thanks to the laboratory's research, numerous undergraduate and graduate theses and several doctoral theses, all purely experimental, are also produced. Finally, the laboratory's consulting and service activities include the results obtained in technical reports to support the design process, shared with research clients.

Main Instrumentation:

The equipment present at LICI includes:

Ripple channel with tilting bottom

U-tube

Educational demonstration channel

The main instrumentation consists of:

Acoustic velocity meter

Pressure probes

Level probes

Image acquisition systems

Contact: cfaraci@unime.it

Supervisor: prof. Giuseppe Di Filippo

European Research Council (ERC):

PE8

Laboratory Location:

Block A, 2nd floor, rooms 201 and 202

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The Geotechnical Laboratory is responsible for the physical-mechanical characterization of natural and reconstituted soils, and mixtures of soils and other materials, for research and applications in the field of Civil Engineering (SSD CEAR-05/A-Geotechnics).

The laboratory is open to students for in-depth teaching of topics covered in the relevant courses, as well as for completing undergraduate and graduate theses.

The laboratory is used for departmental orientation activities for incoming secondary school students and for third-party services serving the local community, which can be classified as Third Mission activities.

Main Activities:

Geotechnical soil characterization is of great importance for assessing foundation and retaining structures, studying landslides and related stabilization interventions, analyzing a site's seismic response, and studying strategically important structures such as dams, bridges, road, port, and railway infrastructure, as well as studying dynamic soil-structure interaction phenomena.

In the context of experimental research, the laboratory focuses primarily on seismic geotechnics, pursued through cyclic and dynamic tests aimed at determining shear modulus, damping, and the relationship between pore pressure and deformation levels. Thanks to the availability of non-standard equipment, these tests allow assessments of the representativeness of experimental results with respect to specimen dimensions.

In addition to teaching and research purposes, the laboratory performs tests for third parties and prepares and issues official certificates in accordance with current regulations. Unit prices for tests are listed in the laboratory price list, which, along with the test request form, can be downloaded at the following link:

https://ingegneria.unime.it/en/research/laboratori

Main Instrumentation:

The Geotechnical Laboratory is equipped with equipment for conducting soil classification and identification tests and for evaluating compressibility parameters (one-dimensional compression tests) and shear strength parameters (direct shear, annular shear, and triaxial compression tests).

For detailed physical characterization, the laboratory has a granulometer for morphometric analysis and an optical microscope for 3D particle reconstruction.

Taking into account the seismic hazard of the city of Messina and the nature of its granular soils, the laboratory is equipped with equipment for performing cyclic triaxial tests and cyclic torsional shear and resonant column tests for medium- and large-sized specimens, to ensure the representativeness of the experimental results.

Two additional rigs are available for triaxial tests with controlled load paths and one rig for direct shear tests on specimens up to 300 mm in size.

Contact: gdifilippo@unime.it

Supervisor: prof. Fabio Todesco

European Research Council (ERC):

PE8_3 PE8_8 PE8_9 PE8_11 SH2_9 SH2_10 SH5_6 SH5_7 SH5_8 SH5_12

Lab Location:

Block A, 3rd floor, rooms 301, 303A, 303B, 305, 306A, 306B

Lab Type:

Research, Teaching, and Services

Brief Description of the Lab:

Lab6R consists of six interconnected sections, each with its own coordinator:

Historical Research (Prof. Francesca Passalacqua) Architectural Survey (Prof. Alessio Altadonna) Architectural Representation (Prof. Adriana Arena) Architectural Restoration (Prof. Fabio Todesco) Redevelopment Technology (Prof. Fabio Minutoli) Urban Regeneration (Prof. Marina Arena)

It aims to act as a link between research, industry, and the local community, capable of building networks and partnerships and providing scientific consulting, support, and guidance in the field of new design and the conservation of existing architecture at various scales, from the landscape to individual buildings, with obvious implications for the teaching provided.

Main Activities:

The 6R Laboratory (Lab6R) aims to synergistically combine the multidisciplinary expertise of the Department of Engineering in the fields of environmental, urban planning, architecture, technology, surveying, representation, and conservation of existing architecture, through a proactive approach capable of combining theoretical knowledge, rigorous methodologies, cognitive investigations, and meta-design solutions. The main activities are:

Surveys of artifacts, creation of georeferenced point clouds using LIDAR technology (laser scanner, drone with GNNS module), and output in CAD format. Consulting and support during both the design and construction phases. Geometric planimetric and altimetric renderings of historic contexts/buildings. Creation of architectural models and prototypes. Urban, territorial, and landscape analysis and assessments. Analysis of surface pathologies and structural damage – definition of the causes. Non-destructive diagnostic investigations. Stratigraphic and archaeometric surveys. Consulting on material compatibility. Evaluation of technical solutions for the energy efficiency of existing buildings. Study, characterization of materials, and definition of their state of degradation through laboratory or on-site analysis and investigations. Development of diagnostic projects in the field of cultural heritage interventions. Creation of materials repertoires according to the prevailing zero-mile and low-cost logic. Development of nZEB (near zero energy building) construction solutions. Training activities.

Main equipment:

WUNDER NHB 200 precision scale. CNC milling machine (3D plotter) [Isel automation Flatcom 20], numerically controlled machine for cutting ductile materials for the production of physical scale models of architecture and urban fabric, with maximum dimensions x=600 mm, y=550 mm, z=250 mm. DJI Mavic 3T Enterprise drone with Wide and Thermal cameras, DJI RC Pro Enterprise remote control, RTK module for support of a GNNS network that guarantees centimeter-level accuracy of surveys. GPS [Garmin GPSMAP 60CSX], for the celerimetric measurement of points in space using a constellation of at least four GPS satellites or for creating dimensioned plans and for tracing paths on maps. Portable universal analog hygrometer [Tramex], non-destructive measurement of moisture content for wood, bricks, masonry, plaster and felt. Laser Scanner [Leica ScanStation II], for the acquisition and generation of point clouds representing the environment and architecture, complete with acquisition and graphic restitution software – 300ml capacity Laser scanner [Leica BLK 360] for the acquisition and generation of point clouds representing the environment and architecture, complete with acquisition and graphic restitution software – 60ml capacity GPS LEICA ZENO FLX100 smart antenna connected to the GNNS network for geolocalisation prior to surveying operations Digital microscope [50X – 200X], connected to a laptop, allows you to obtain images with magnifications in the range of 50-200X. Pocket laser meter - Digital inclinometer [Leica Disto D3], for fast and extremely precise measurement of distances between even inaccessible points and angles. Flir E8-XT thermal imaging camera for detecting surface temperatures. Multifunction cover meter [Covermaster with P331-H corrosion analysis kit], for locating reinforcement in concrete, measuring concrete cover, automatic calculation of bar diameter and measurement of potential for corrosion assessment. REBAR Dr3000 Rl type cover meter/rebar locator with 145mm detection depth A0+ plotter [Canon IPF 8000S], for high-quality printing of all digital processing produced A0+ roller scanner [Colortrac SmartLF CX40], for the acquisition of maps/plans A3+ flatbed scanner [Epson GT 12000], for the acquisition of documents/photos ASTORI type sieve shaker with sieves Allows the granulometric analysis of the base materials Portable spectrophotometer [Konica Minolta CM2600d], equipped with a diffused illumination system with a spectral range of 400-700 nm. It objectively evaluates, through the acquisition of reference colorimetric coordinates, the chromatic appearance and any variations over time of finishing systems. Workstation [HP Z8 G4 with NVIDIA Quadro P4000 video card] and related monitor. Laptop LENOVO Thinkpad P2 Mortar Penetrometer [NOVATEST PRD 800] for determining the resistance of plasters or bedding mortars. Motorized total station [Leica Nova MS50 MultiStation] for acquiring points even at considerable distances from the surveying station and generating point clouds representative of the environment and architecture, complete with acquisition and graphic rendering software. Sonic and ultrasonic instruments [VTE 40K/16 Workstation] allow for assessing the structural integrity of masonry, concrete, and wood structures, detecting their state of deterioration. It is used to characterize the morphology of the elements, identifying the presence of cavities, voids, or cracks, and assessing their depth. Video endoscope [Boviar videoprob 300] for naked-eye or camera-based inspections of inaccessible cavities to investigate the composition of the masonry, any cavities, internal cracks, and the paths followed by the injected mixtures. PLA 3D printer for real-life reproduction of scale models.

Contacts: ftodesco@unime.it

Supervisor: prof.ssa Ornella Fiandaca

European Research Council (ERC):

PE8_3 SH5_8 SH5_12

Laboratory Type:

Research and Teaching

Brief Description of the Laboratory:

The laboratory was established in 2016 to recover a century of history scattered among difficult-to-access sources scattered throughout the country, not just locally. Gathering and systematizing available real and virtual materials and developing effective elaboration, with the aid of digital approaches, has been a task undertaken since its inception in synergy with all cultural, institutional, and social stakeholders. The results are unprecedented contributions to the understanding of the processes that have affected the city, from the earthquake to the present, and provide elements for critical evaluation for future actions.

Main Activities:

The interdisciplinary composition of the research group (Area 08A: CEAR-08/A, CEAR-10/A, CEAR-11/A, CEAR-12/A) enables in-depth exploration of topics from a historical-architectural, urban planning, metric, technical-construction, and material perspective, as well as a digital approach for the preservation of the consulted documentary heritage and the multiple elaborations produced. Events, exhibitions, scientific and popular publications, framework agreements with institutions (Messina Municipality, Archive Superintendency for Sicily, Messina Court of Appeal), institutional service activities (General Directorate for Contemporary Creativity of the Ministry of Culture), web products, degree and doctoral theses, and teaching experiences are examples of the results and actions undertaken to create reciprocal relationships between the Department of Engineering and the local community.

Main Equipment:

The laboratory has a computer station.

Contact: ornella.fiandaca@unime.it

Supervisor: prof. Massimo Di Gangi

European Research Council (ERC):

SH3_9

Laboratory Location:

Block A, Floor 6, Room 612

Laboratory Type:

Research and Teaching

Laboratory Brief Description:

The LAST is located within the Department of Engineering at the University of Modena (ME). It conducts research in the field of Transport Engineering and Logistics for land, sea, and air transport using approaches such as demand analysis, simulation, and network design under ordinary and emergency conditions. It also offers courses on freight transport and logistics, Smart Cities, and Intelligent Transport Systems.

Main Activities:

Development and application of methodologies for transport system analysis, traffic management, and land-use planning. Research focuses on:

static and dynamic traffic assignment to congested road networks and public transportation systems; transportation demand analysis and assessment methodologies; distribution analysis and modal choice in freight transport (city logistics and sustainable distribution); maritime transport; analysis of transportation systems in emergency conditions; simulation of evacuation of buildings and high-risk areas; functional assessment of transportation systems and the resilience of transportation networks.

Support activities and collaborations with organizations and institutions such as the Institute of Advanced Technologies for Energy (CNR-ITAE), the Sicilian Highways Consortium (CAS) and Autostrade dei Fiori (ASTM Group), and the Strait of Messina Port Authority (AdSP Strait).

Main equipment:

The laboratory is also equipped with video and license plate recognition equipment for traffic flow monitoring, as well as magnetic and radar solutions.

Contact: last@unime.it

Supervisor: prof. Orazio Pellegrino

European Research Council (ERC):

--

Laboratory Location:

Block A, 7th Floor, Room 721

Lab Type:

Research and Teaching

Lab Brief Description:

The ultimate goal of DiLARS is to improve road safety through the provision of experiments in a simulated environment in which all elements of the road system (vehicle, pavement, environment, and driver) can be specifically designed and monitored using numerous variables. Although the hardware consists of a static structure, the control software is particularly sophisticated and allows for extreme flexibility in selecting road geometry, vehicle type, traffic, and environmental conditions.

Main Activities:

Bachelor's and Master's students are trained to evaluate infrastructure design not only in light of current regulations but also with regard to behavior and the impact on humans, who are responsible for a large proportion of road accidents.

In terms of research, the laboratory's spectrum of applications is extremely broad, as it can consider specific infrastructure geometries (even non-existent ones), the role of the vehicle and, in particular, its driver assistance systems (ADAS), and the detailed psycho-physiological aspects of the driver.

Simulated driving is often the only way to test contexts considered dangerous (due to geometric, weather, or traffic conditions), innovative elements not yet available on the market (signs, barriers, etc.), or to test the dangerousness of certain categories of drivers (elderly drivers, users with a particular propensity for risk, alcohol and drug users).

Main instruments:

AVSimulation SIM-EASY driving simulator, equipped with Scaner software. Neon Pupil Eye Tracker for measuring visual behavior (fixations, saccades, pupil size, blinks). Shimmer sensors for measuring heart rate and skin conductivity. G923 steering wheel, Logitech Trueforce gear shifter and pedals. META QUEST 3 VR headset.

Contacts: opellegrino@unime.it

Supervisor: prof. Ernesto Cascone

European Research Council (ERC):

PE_8

Laboratory Location:

Viale Ferdinando Stagno d’Alcontres, 98166, S. Agata, Messina

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The C.E.R.I.S.I. Geotechnical Engineering section is a national and international laboratory of excellence for conducting experimental investigations on scaled physical models of geotechnical and structural structures and systems. The laboratory conducts contract work and research in the fields of seismic geotechnical engineering (SSD CEAR-05/A Geotechnics) and structural engineering (SSD CEAR-06/A Building Science).

Main Activities:

The laboratory performs shaking table tests on small-scale physical models of geotechnical and structural structures and systems. The one-dimensional shaking table is equipped with a large container (currently the largest in Europe) with flexible walls (laminar box) that reproduces the deformation conditions that characterize soil deposits traversed by seismic waves. The equipment is complemented by an automatic soil deposition system that allows for the creation of deposits of a predetermined degree of density. Finally, the laboratory is equipped with equipment for monitoring the behavior of the models during testing.

Main instrumentation:

The instrumentation consists of a shaking table driven by a unidirectional servo-hydraulic actuator that reproduces the motion typically associated with a seismic event. A flexible-walled laminar box container with lengths, widths, and heights of 6 m, 1.5 m, and 2 m is also present. For the creation of geotechnical models, the equipment is complemented by a rainwater deposition system using a traveling hopper with adjustable speed and drop height. The behavior of the physical models being investigated experimentally is monitored using a wide range of measurement instruments that, via an acquisition system, record displacement and acceleration time histories in real time.

Contact: ecascone@unime.it

Supervisor: prof. Giuseppe Ricciardi

European Research Council (ERC):

PE8

Laboratory Location:

Viale Ferdinando Stagno d’Alcontres, 98166, S. Agata, Messina

Laboratory Type:

Research and Services

Laboratory Brief Description:

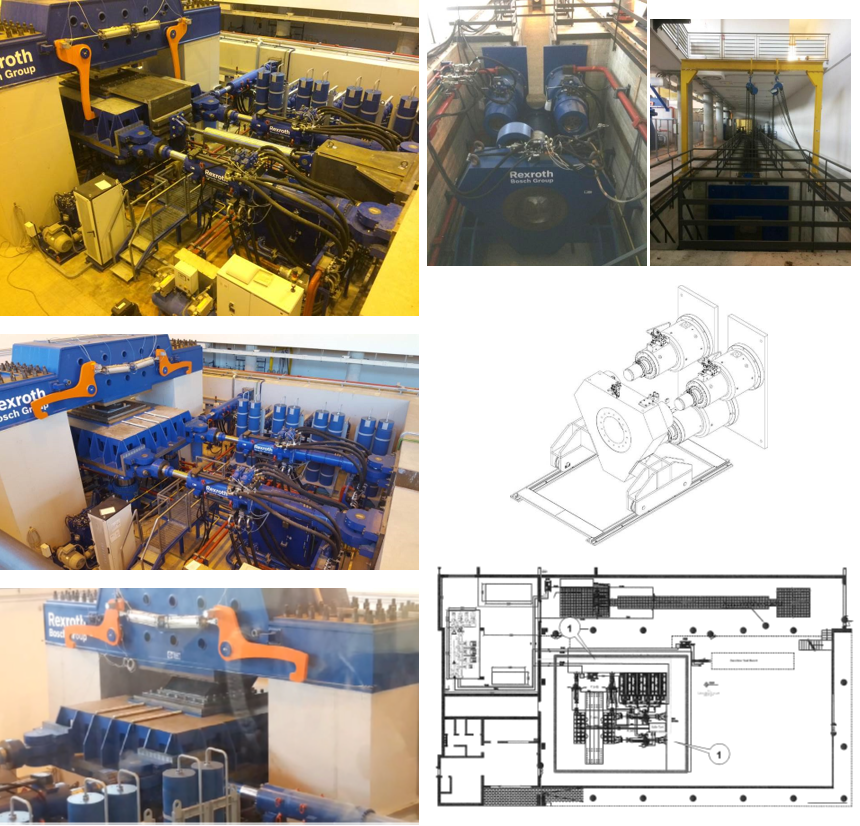

The Laboratory, using innovative equipment, allows testing of structures and structural components by simulating real-world conditions, both static and dynamic, and serves as a reference laboratory for planning and executing special tests in the fields of structural engineering and earthquake engineering.

With a view to potential collaboration with international research centers, the Laboratory also presents itself as a suitable partner for experimentation in the development of new design codes.

Main activities:

The Laboratory consists of:

A dedicated test system that assesses the compliance of seismic devices with the requirements of UNI EN 15129, ensuring the versatility needed to conduct test campaigns for the experimental characterization of devices (dampers, elastomeric isolators, etc.) both during product qualification and during acceptance and production control. The test rig also allows for the execution of various types of tests for combinations of these devices. A test rig for the qualification and acceptance of cables, ropes, and stays with up to 109 strands, in accordance with the recommendations of FIB Bulletin No. 30 and PTI DC45.1. The current test rig configuration allows for tests with a maximum frequency of 1.0 Hz.

Main instrumentation:

The equipment for testing seismic devices consists of:

a sliding table with plan dimensions of the effective load surface: 2 m x 2 m x 1 m; Four servo-actuators positioned underneath the table to support it, each with a maximum total vertical load of 16 MN under dynamic conditions and a stroke of ±35 mm; two low-friction, high-speed servo-actuators, used to move the table in the longitudinal direction, each with a maximum total load of ±3.1 MN and a stroke of ±550 mm; two low-friction, high-speed servo-actuators, used to move the table in the transverse direction, each with a maximum total load of ±1.4 MN and a stroke of ±375 mm; a dedicated hydraulic power unit for cylinder movement, complete with an electronic control unit and management software application; a set of accelerometer sensors and LVDT (Linear Variable Differential Transformers) transducers for monitoring significant physical parameters during the test.

The versatility of the equipment allows, with the necessary agreed-upon technical adjustments, the system configuration to be modified for ad hoc experimental tests on structural and non-structural elements (for example, but not limited to: large-capacity load cells, mechanical components).

The cable testing system consists of:

a reinforced concrete trench with a total length of 30.6 m for testing cables up to 22 m in length; three double-rod hydraulic servo-actuators with a maximum total static force of 31 MN and a dynamic force superimposed on the static force of 3.3 MN, a total stroke of 500 mm (single cylinder rod stroke equal to 250 mm + spacer length equal to 250 mm); one servo-actuator for radial loading on the cable being tested.

The versatility of the equipment allows, with the necessary technical adjustments, the performance of preparatory tests even for testing large-diameter ropes in compliance with the requirements of reference standards such as UNI EN 12385-1.

Contact: gricciardi@unime.it