Supervisor: prof.ssa Chiara Borsellino

European Research Council (ERC):

PE8_7 PE8_9

Laboratory Location:

Block A, Floor 0, Room 001

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory is equipped with general-purpose machine tools, both manual and CNC. The main scientific area involved is 09-IIND/04 – Processing Technologies and Systems, as it carries out mechanical processing activities, such as the creation of mechanical connections for friction stir welding, general mechanical connections, and the study of tools and processes. The laboratory also provides support for experimental research across the department's other laboratories through the creation of prototypes, equipment, test specimens, molds, etc., or the cutting of materials and components.

The laboratory conducts teaching support activities, such as exercises and year-round projects for Mechanical Technology courses, and degree theses for Industrial, Mechanical, and Management Engineering courses.

Activities:

The main research activities conducted in the laboratory involve the machining of mechanical components such as molds, tool testing, and the identification of optimal cutting or machining parameters such as friction stir welding.

In addition, support activities for other areas involve the manufacturing of components for the repair or integration of existing machines or equipment, the cutting of specimens for metallography, and the cutting of specimens for tensile/flexural/torsional testing.

Teaching-related activities include the implementation of student-designed machining cycles or simple machining demonstrations, and the implementation of machining operations related to student thesis work.

Contract work is also carried out for third parties, involving the production of prototypes and the machining of metal specimens.

Main equipment:

Numerical control machine tools: YAMAZAKI MAZAK QUICK TURN NEXUS 200MY mk II NC horizontal spindle turning center - a machine capable of performing multiple machining operations (turning, milling, drilling, and threading) on axisymmetric components. MAZAK Variaxis I600 five-axis motorized machining center. Machining operations: turning, milling, drilling, boring, and tapping for components of all shapes.

Manual machines: ITAMA FV 60-ing 3.75 kW turret milling machine, pillar drill. Drilling capacity in steel: 40 mm, spindle motor power: 1.1 - 1.5 kW. Metal band saw.

Tools and support equipment for machining operations such as hacksaws, files, vices, shears, pliers, wrenches, and screwdrivers.

Contact: cborsellino@unime.it

Supervisor: prof. Vincenzo Crupi

European Research Council (ERC):

PE8_12 PE8_7 PE8_10 PE8_3 PE8_14

Laboratory Location:

Block A, Floor 0, Room 001

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The dimensions of the slatted floor and frame, and the presence of various types of actuators with the possibility of applying up to 10 actuators simultaneously, allow for static and dynamic tests to determine the mechanical characterization and fatigue life of large structural components and welded joints.

The laboratory manager is Vincenzo Crupi, full professor of Naval Construction and Systems (IIND-01/B) and head of the Nettuno research group in the Department of Engineering.

The laboratory's expertise covers Naval Construction and Systems (IIND-01/B) and Mechanical Design and Machine Construction (IIND-03/A).

Main activities:

Full-scale mechanical fatigue, tensile, compressive, and flexural tests. Dynamic fatigue characterization tests, with the possibility of various load configurations, of steel and composite structural elements for the naval, offshore, railway, automotive, and mechanical sectors. Full-scale tests on large structures subjected to real-life dynamic load conditions during operation.

Main equipment:

Grated floor measuring 12.5 x 8.5 m – h = 1 m; 1 modular gantry with overall dimensions of 9x7 m - h = 5 m; 2 test benches with dimensions of 1x1 m - h = 1.5 m; 2 reaction arms with dimensions of 0.8x4 m and 0.8x2.5 m; 1 bending gripping system with supports and thrust rollers 1 m wide; 12 servo-hydraulic actuators with nominal capacity and stroke of 1 MN and ±100 mm (2 actuators), 500 kN and ±100 mm (2 actuators), 250 kN ±100 mm (4 actuators), 100 kN ±100 mm (4 actuators); manifold, hydraulic power unit equipped with refrigerator, oil distribution system, electronic control unit, and dedicated software.

Contact: crupi.vincenzo@unime.it

Supervisor: prof. Guido Di Bella

European Research Council (ERC):

PE8_7 PE8_8 PE8_9 PE8_10 PE8_11 PE8_12

Laboratory Location:

Block A, 1st floor, rooms 101A and 101B

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory's activities are aimed at developing advanced production technologies, with particular emphasis on Additive Manufacturing, through the optimization of process parameters, the design and prototyping of innovative structures (e.g., TPMS, functional gradient materials, metamaterials), and their industrial applications. The expertise falls within the scientific-disciplinary sector IIND-04/A – Manufacturing Technologies and Systems (formerly ING-IND/16).

Main activities:

The laboratory conducts research in the field of Additive Manufacturing, with a focus on the extrusion deposition of polymeric materials, both pure and fiber-reinforced. Activities focus on process optimization and the exploration of new design solutions, including TPMS structures for sandwich panels and heat exchangers, as well as functional components such as hybrid joints obtained entirely by 3D printing. The laboratory also conducts reverse engineering, applied to the geometric characterization and digital reconstruction of naval components and prototypes. It actively collaborates with the CNR-ITAE Additive Manufacturing Laboratory and local companies. It also provides teaching and training support, orientation for high school students, and third mission initiatives, promoting the dissemination of technical and scientific knowledge through events, workshops, and practical demonstrations.

Main equipment:

The laboratory is equipped with next-generation FFF 3D printers, both open and closed chamber, with single-material and multi-material configurations. Some are equipped with heated chambers, allowing the processing of technical materials such as ABS. A structured-light 3D scanner is available, suitable for reverse engineering small and medium-sized mechanical components. The lab also has a wide range of filaments: from standard polymers to materials reinforced with natural, glass, or carbon fibers, as well as conductive, elastic, and high-performance materials. The equipment allows for the study and prototyping of complex geometries and the creation of functional samples. To support these activities, a space dedicated to design, technical documentation, and data processing is also available, which also serves as an operations office for students and researchers.

Contacts: guido.dibella@unime.it

Supervisors: prof. Antonio Cimino, prof. Vincenzo Corvello, prof.ssa Maria Francesca Milazzo

European Research Council (ERC):

PE8_2 SH1_11

Laboratory Location:

Block B, Floor 4, Room 437

Laboratory Type:

Research

Laboratory Brief Description:

The laboratory aims to promote an integrated approach that combines technological innovation, human capital development, and business process optimization, addressing the contemporary challenges of Management Engineering. Activities will be developed within the following scientific disciplines:

IEGE-01/A – Management Engineering: with a focus on technological innovation, strategic skills management, process optimization, and well-being in the workplace. ICHI-02/A and ICHI-02/B – Industrial Plants and Technologies: with a focus on control and safety systems, risk management, and predictive maintenance.

Main activities:

Technological innovation and strategic skills management: The laboratory conducts research aimed at developing models and tools that integrate advanced digital solutions, managerial practices, and human resources management to support business competitiveness. Business process optimization and management: Continuous improvement strategies are analyzed and tested to increase the operational efficiency and sustainability of production and management processes. Human well-being and sustainability in the workplace: The laboratory studies how innovative technologies and new organizational models can contribute to improving the quality of working life, with particular attention to workers' physical and mental well-being. Control and safety systems: Innovative solutions that combine advanced technologies and human skills are designed and tested, with the aim of ensuring the reliability and efficiency of industrial processes, improving the safety of people and complex production environments. Risk management and predictive maintenance: The laboratory develops and tests predictive technologies to proactively address risk management, improving the reliability and longevity of systems, and reducing costs and failures through advanced maintenance models.

Main instrumentation:

In Installation

Contacts: mariafrancesca.milazzo@unime.it; vincenzo.corvello@unime.it; antonio.cimino@unime.it

Supervisor: prof. Antonio Galvagno

European Research Council (ERC):

PE8_5 PE8_6

Laboratory Location:

Block C, Floor 2, Room 260

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory is equipped to conduct experimental tests on internal combustion engines, with a focus on atmospheric pollutant emissions, fuel consumption, performance, and exhaust gas aftertreatment systems. These tests are conducted on internal combustion engines fueled with conventional and/or bioderived fuels, blended with conventional or pure fuels, or with bioderived gaseous fuels. The aim is to evaluate the differences in fuel consumption, emissions, and performance compared to the use of commercial fuels. Hybrid, battery-electric, and fuel-cell vehicles are also studied for the correct sizing of components and the development of control strategies that optimize energy flows, overall efficiency, and emissions.

Activities:

Characterization of internal combustion engines (performance, fuel consumption, and gaseous and particulate emissions)

Characterization of conventional and alternative fuels

Characterization of hybrid vehicles

Main instrumentation:

Internal Combustion Engine Test Bench:

Eddy current brake for engines up to 260 hp

Fuel consumption measurement scale

Combustion chamber pressure measurement system

Exhaust gas analysis system (CO: 0-15% vol, CO2: 0-20% vol, HC: 0-30,000 ppm vol, O2, 0-25% vol, NO: 0-5,000 ppm vol)

Particulate matter measurement system with particle number detection (from 5.6 to 560 nm)

Software:

AVL BOOST™, AVL EXCITE™, AVL FIRE™

Contact: antonio.galvagno@unime.it

Supervisor: prof. Vincenzo Crupi

European Research Council (ERC):

PE8_7 PE8_10 PE8_12 PE8_14

Laboratory Location:

Block C, 2nd Floor, Room 260

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

Laboratory activities include performing static and dynamic tests to qualify the mechanical properties of traditional and innovative materials and welded joints, according to current standards, even in hostile environments and at different temperatures.

The laboratory also offers the possibility of checking for defects in welds or small components.

The laboratory director is Vincenzo Crupi, Full Professor of Naval Construction and Systems (IIND-01/B) and Head of the Nettuno research group in the Department of Engineering.

The laboratory's areas of expertise include Naval Construction and Systems (IIND-01/B) and Mechanical Design and Machine Construction (IIND-03/A).

Main activities:

Mechanical testing of fatigue, tensile, compression, torsion, flexure, and fracture mechanics; Creep testing; Drop testing, Izod and Charpy impact; Indentation testing; X-ray testing of welds, composites, and mechanical components.

Main equipment:

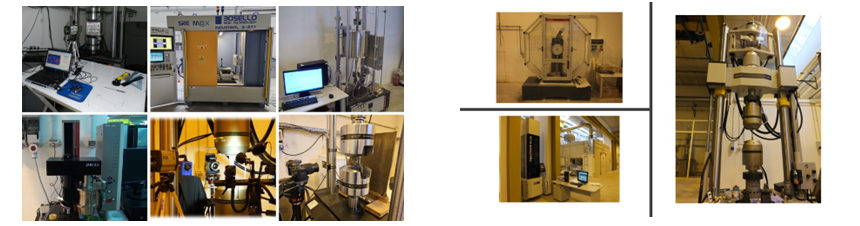

Impact testing machine (FRACTOVIS PLUS CEAST) equipped with a climate chamber. Universal testing machine (INSTRON 8803) with a 500 kN load cell for static and dynamic tests. Universal axial-torsional testing machine (INSTRON 8850) with a 250 kN load cell for static and dynamic and fracture mechanics tests, equipped with a climate chamber. Universal testing machine (MTS 810) with a 250 kN load cell for static and dynamic tests. Vickers, Brinell, Rockwell, and indentation testing machine (Zwick/Roell KAPPA 50 LA). Creep testing machine (Zwick/Roell). 450-J Charpy pendulum (Zwick/Roell). X-ray cabinet with 320 kV source (Bosello SRE M@X - 320 kV). Muffle furnace (Thermal Engineering).

Contact: crupi.vincenzo@unime.it

Supervisor: prof.ssa Gabriella Epasto

European Research Council (ERC):

PE8_7 PE8_10 PE8_12 PE8_13

Laboratory Location:

Block C, 2nd Floor, Room 261

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The activities developed in the Tomography Laboratory include non-destructive testing of lightweight materials (laminates, sandwich panels, light alloy structures) and joints (welding and bonding) for the design of biomechanical, mechanical, and naval structures.

The expertise is in the fields of Mechanical Design and Machine Construction (IIND-03/A) and Naval Construction and Systems (IIND-01/B).

Main activities:

Non-destructive testing of welds

Non-destructive testing of composite materials and lightweight structures

Non-destructive testing of porous and lattice structures

Flaw analysis of structures

Detection of structural damage due to mechanical loads on joints and lightweight structures

Main equipment:

X-ray tomography with 225 kV tube

Contacts: gabriella.epasto@unime.it

Supervisor: prof. Filippo Cucinotta

European Research Council (ERC):

PE8_8 PE8_10 PE8_11 PE8_12

Laboratory Location:

Block C, Floor 3, Room 360

Laboratory Type:

Research and Teaching

Laboratory Brief Description:

The laboratory is part of the Industrial Engineering Design and Methods Scientific Disciplinary Sector (IIND-03/B) and is dedicated to research and teaching. Its primary objectives are the study, application, and teaching of digital representation and prototyping techniques in industrial engineering.

Main Activities:

The laboratory's main activities include research and teaching on 3D acquisition and 3D printing techniques. Depending on the available equipment, methods based on photogrammetry, structured-light 3D scanning, and LiDAR technology are used. 3D printing is achieved using material extrusion (MEX) technologies, specifically Fused Deposition Modeling (FDM).

Main equipment:

The lab features three 3D scanners: two structured-light scanners and one LiDAR-based scanner, which differ in portability, resolution, and scope of use. A photogrammetry kit is available, consisting of a fixed-focal-length reflex camera and setup calibration tools. For 3D printing, systems based on MEX (Material Extrusion) technology are used to produce objects using Fused Deposition Modeling (FDM).

Contact: filippo.cucinotta@unime.it

Supervisor: prof. Vincenzo Crupi

European Research Council (ERC):

PE8_3 PE8_12

Laboratory Location:

Block C, Floor 3, Room 361

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

Laboratory activities include numerical simulations of fluid-structure interaction of naval structures and experimental tests using sensor applications on naval components.

The laboratory director is Vincenzo Crupi, Full Professor of Naval Construction and Systems (IIND-01/B) and Head of the Nettuno research group in the Department of Engineering.

The laboratory's expertise covers Naval Construction and Systems (IIND-01/B) and Naval Architecture (IIND-01/A).

Main activities:

Modeling and Finite Element Analysis with fluid-structure interaction in the naval and offshore sectors. Sensors for the structural integrity of vessels and naval components. Sensors onboard vessels. Indentation tests.

Main instrumentation:

Portable diaptometer, strain gauges, accelerometers, control unit, trigger box, sensors

Contact: crupi.vincenzo@unime.it

Supervisor: prof. Vincenzo Crupi

European Research Council (ERC):

PE8_7 PE8_10 PE8_12

Laboratory Location:

Block C, Floor 3, Room 362

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

Laboratory activities include ultrasonic fatigue testing and static and fatigue mechanical tests, including the application of the Digital Image Correlation (DIC) technique.

The laboratory director is Vincenzo Crupi, Full Professor of Naval Construction and Systems (IIND-01/B) and Head of the Nettuno research group in the Department of Engineering.

The laboratory's areas of expertise include Naval Construction and Systems (IIND-01/B), Naval Architecture (IIND-01/A), and Mechanical Design and Machine Construction (IIND-03/A).

Main activities:

Mechanical fatigue, tensile, compression, and flexural tests; Ultrasonic fatigue tests; Strain state analysis using DIC technique.

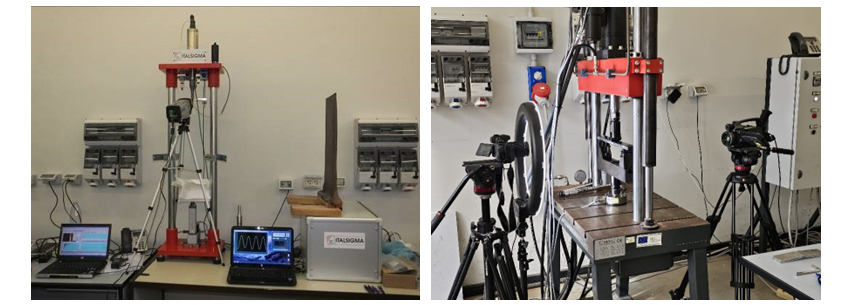

Main equipment:

Machine (ITALSIGMA) for very high-cycle fatigue testing. Universal machine (ITALSIGMA) with 12.5 and 25 kN load cells for static and fatigue tests. Digital Image Correlation (DIC) system (GOM).

Contact: crupi.vincenzo@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE4_16 PE11

Laboratory Location:

Block C, Floor 3, Room 363

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory specializes in testing materials and devices for exposure to aggressive or controlled environments. Specifically, salt spray or acetic acid salt spray exposure tests, as well as thermo-hygrometric tests with wet-dry and cold-hot cycles in controlled environments and under UV radiation, are available.

Main Activities:

Activities focus on evaluating the durability of materials (metal alloys, coatings, composites) or systems and components (e.g., metal joints, bimetallic or bi-material joints), and material aging in accelerated exposure tests.

The laboratory also offers third-party services for material characterization:

Continuous salt spray tests, conducted at a single adjustable temperature, such as ASTM B117, UNI EN ISO 9227, JIS Z 2371, etc., with neutral pH salt solutions (NSS) or acidified test solutions with the addition of acetic acid (ASS) or cupric acid (CASS). Accelerated aging tests for exposure to accelerated climate cycles (temperatures between -70°C and +150°C and relative humidity from 10% to 100% RH), e.g., according to STM D4799 / D4799M – 17 or UNI EN 1297:2005.

Main equipment:

Angelantoni ACS Challenge 250 climatic chamber, Angelantoni DCTC 600P salt spray chamber, Ascott S450iS salt spray chamber

Contacts: edoardo.proverbio@unime.it

Supervisor: prof.ssa Candida Milone

European Research Council (ERC):

PE5_1 PE5_2 PE5_3 PE5_6 PE5_8 PE5_9 PE5_10 PE5_13 PE5_18 PE5_19 PE8_9 PE11_4 PE11_5 PE11_6 PE11_7 PE11_8 PE11_9 PE11_10 PE11_11

Laboratory location:

Block C, 4th floor, room 460

Laboratory type:

Research and teaching

Laboratory brief description:

The Materials for Energy and the Environment Laboratory conducts research in the fields of chemistry for technologies and materials science (CHEM-06/A, IMAT-01/A) with a focus on the development of innovative solutions for energy and environmental sustainability. It supports teaching through the development of master's and doctoral theses and integrates the experimental activities conducted in other laboratories within the Department, fostering interdisciplinary synergies.

Main Activities:

The Laboratory conducts synthesis, characterization, and study of innovative materials for energy and environmental applications, such as energy conversion and storage, catalysis, and sustainable processes. Its expertise includes the preparation of new functional materials, analytical and physicochemical investigations, and evaluation of porosity properties and adsorption/desorption processes. The laboratory offers support to students and researchers in the development of theses and research projects, experimental training activities, and collaboration with other groups within the Department and external institutions, promoting technology transfer and interdisciplinary approaches.

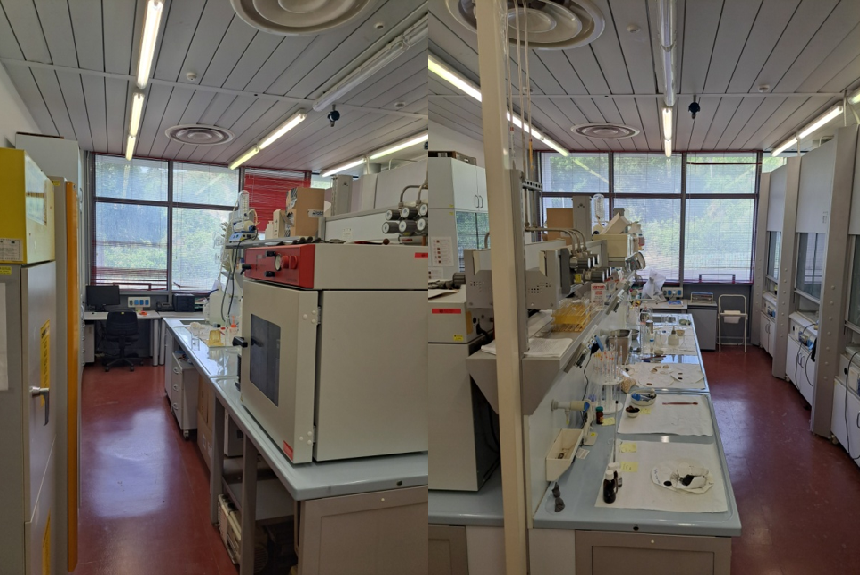

Main Instrumentation:

The Laboratory is equipped with advanced instrumentation for chromatography and mass spectrometry (GC-MS, HPLC-MS, TOC and nitrogen systems), useful for analytical and environmental analysis. Equipment is available for the chemical and physical characterization of materials, including instruments for determining surface area, porosity, adsorption and desorption, and viscometry. The laboratory also has furnaces, heating and heat treatment systems (tubular furnaces, ovens, hotplates), and supporting instruments such as scales, pH meters, sonicators, vacuum pumps, and stirrers. These facilities enable integrated synthesis, treatment, analysis, and characterization of innovative materials for energy and environmental applications.

Contacts: candida.milone@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE3 PE5 PE11

Laboratory Location:

Block C, Floor 4, Room 461

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory houses two field-emission scanning electron microscopes equipped with energy-dispersive microanalysis (EDS): the FEI Quanta FEG 450 and the Zeiss CrossBeam 540 SEM-FIB.

The laboratory is used in all areas of materials science, chemistry, and engineering, for research and third-party services for materials study and characterization and failure analysis.

Main activities:

Investigations and characterization services for research on inorganic and organic solids. Investigations in low-vacuum environments and in the presence of water vapor (FEI Quanta FEG 450). EDS microanalysis (elemental composition of materials) with punctual or mapping. Investigations of powders and solids of metallic, ceramic, or polymeric materials, composites, and fibers. Surface texture investigations. Failure analysis.

Main instrumentation:

FEI Quanta FEG 450 low-vacuum scanning electron microscope (SEM) Zeiss CrossBeam 540 field-effect emission scanning electron microscope (SEM) and gallium focused ion beam (FIB) for etching and surface patterning.

Contacts: edoardo.proverbio@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE3 PE4 PE5 PE11

Laboratory Location:

Block C, Floor 4, Room 463

Laboratory Type:

Research and Services

Laboratory Brief Description:

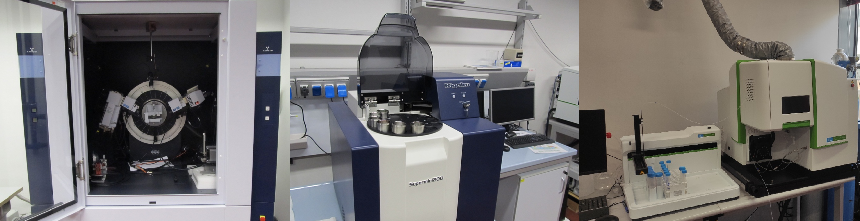

The laboratory, which houses a Brucker Advance D8 diffractometer, a Rigaku X-ray fluorescence spectrophotometer (Supermini 200), and an Avio 220 Max ICP-OES optical emission spectrophotometer, is used in a wide range of scientific disciplines to support basic and applied research.

Main Activities:

Analysis and characterization services for research and third-party investigations of inorganic and organic solids for phase recognition and elemental analysis.

Investigations of powders and solids of metallic, ceramic, or polymeric materials, composites, and fibers.

Main instruments:

Bruker Advance D8 X-ray diffractometer, Rigaku Supermini 200 X-ray fluorescence spectrophotometer, Avio 220 Max ICP-OES optical emission spectrophotometer

Contacts: edoardo.proverbio@unime.it

Supervisor: prof.ssa Annamaria Visco

European Research Council (ERC):

PE5_6 PE8_8 PE8_11

Laboratory Location:

Block C, Floor 4, Room 466

Laboratory Type:

Research

Laboratory Brief Description:

The laboratory studies and performs the physical and mechanical characterization of polymers, biopolymers, and composites, both pure and blended, chemically and/or physically modified.

Analysis can be performed on both the surface and the whole material (bulk), before and during various treatments (e.g., artificial aging, hydrolytic degradation, photodegradation, etc.), or before and after mixing with various additives (plasticizers, antioxidants, pigments, UV inhibitors, etc.).

Main activities:

Surface properties testing of coatings: roughness tester, thickness gauge, cross-cut test, artificial aging with UV lamp, DSC thermal analysis, melt flow index

Main equipment:

Mini-laboratory twin-screw extruder, Brabender mixer, hydraulic press for simple thermoforming, Izod impact machine, prototype for wear determination, prototype for determining surface wettability, tensile test machine with thermal chamber, Shore D durometer, rotational rheometer, pelletizer

The mini-extruder is a co-rotating twin-screw instrument capable of creating extruded wires of various geometries on a laboratory scale. The extrusion chamber volume is 7 cm3. These machines have two screws in the extrusion barrel. This offers advantages such as forced material transport rather than drag, shorter processing time, reduced material residence time in the extruder barrel, and self-cleaning of the screws.

The mixer has a mixing chamber, consisting of a cavity within the metal block (frame) containing the counter-rotating steel rotors. Rotor speed and chamber temperature can be adjusted manually using controls on the machine's control panel and continuously monitored using dedicated software installed on the computer to which the mixer is interfaced. Materials are fed into the chamber through a hopper, where they are heated and mixed by the action of the two rotors. Variations in torque can be recorded.

The tensile test machine is used to determine the mechanical behavior of a material subjected to static tensile stresses applied at the center of gravity of the material cross-section and acting along the body axis. These tests are performed on dog-bone specimens with a rectangular cross-section and are equipped with two ends used for clamping to the machine (called "specimen heads"). Therefore, the useful length of the specimen, on which the deformation measurements are performed, is less than its total length. The shapes of these specimens are standardized for each type of material according to the ASTM 638 M-3 standard.

The mechanical parameters that can be determined are:

Young's modulus; percent elongation; yield strength; ultimate tensile strength; and toughness.

The first four characteristics are determined through static tensile testing, while the last, toughness, is obtained by calculating the area of the stress-strain curve.

The rheometer allows dynamic viscosity measurements and operates in flow, allowing sample analysis in terms of flow curves.

Contact: avisco@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE4 PE5 PE8_6 PE11

Laboratory Location:

Block C, Floor 4, Room 465

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory specializes in the synthesis and characterization of metallic and inorganic materials, with a focus on energy materials (energy storage) and materials for low-temperature thermal energy utilization.

Main Activities:

Research activities include: design and development of materials with high heat storage and release capacities, both through adsorption and thermochemical processes, for use in industrial and domestic applications; development of innovative materials for collecting and recovering water from the environment, with a focus on technologies based on hydrophilic materials that facilitate water condensation and transport.

Research is also conducted aimed at the development, characterization, and optimization of composite materials for innovative coatings to be used to improve the efficiency of thermal energy recovery and reuse systems (e.g., coatings and technologies for energy storage or adsorption heat pumps, materials for thermal energy storage).

The laboratory also offers third-party services for material characterization:

Steel and metal alloys: S, C, N, O analysis; Porous materials (adsorption measurements in water vapor at variable temperature and pressure); Thermal properties of materials; Polymeric materials: mechanical and thermomechanical properties (DMA).

Main equipment:

2.5 kN Zwick Line universal testing machine (Zwick Roell, Ulm, Germany), equipped with a 2.5 kN cell; Netzsch DMA 242 E Artemis dynamic mechanical analysis machine; DVS Vacuum dynamic thermogravimetric vapor analysis system (Surface Measurements Systems, Middlesex, UK). LECO TC400 Nitrogen/Oxygen Analyzer for Metals and Ceramics. LECO CS 230 Carbon/Sulfur Analyzer for Metals and Ceramics. Tube furnaces and glove box for work in the absence of oxygen and water vapor.

Contact: edoardo.proverbio@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE3 PE5 PE11

Laboratory Location:

Block C, Floor 4, Room 466

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory houses a JEOL JEM-2100 transmission electron microscope (TEM) capable of operating at an accelerating voltage of up to 200 kV. The microscope is used for high-resolution imaging and materials analysis. It is a versatile instrument, often used to study the microstructure and composition of various materials. The lanthanum hexaboride (LaB6) source ensures high brightness for high-contrast, high-resolution images.

It is used in various fields, including materials science, biology, and nanotechnology, to study the micro- and nanostructure and properties of a wide range of materials.

Main activities:

Analysis and characterization services for research and third-party investigations of inorganic and organic solids for the study of nanostructures and phase recognition (e.g., in the field of catalysis)

Investigations of powders and solids of metallic and ceramic materials (in thin lamellae)

Main instrumentation:

JEOL JEM 2010 transmission electron microscope (LaB6 source), equipped with a Gatan 794 Multi-Scan CCD digital imaging camera.

Contact: edoardo.proverbio@unime.it

Supervisor: prof.ssa Annamaria Visco

European Research Council (ERC):

PE5_6 PE8_8 PE8_11

Laboratory Brief Description:

The laboratory houses an automated plant for processing agri-food waste using the "Mechanical Treatment Prototype," or "MTP," envisioned as part of the LIFE 2021_ENV-IT_LIFE RESTART project (LIFE 2021_SAP-ENV-101074314). This involves a series of sequential steps and comprises:

grinding system; sieving system; dehumidification system; dosing system; weighing system; vacuum system for material storage; quality control system; and a PC for acquiring moisture loss curves, wettability analysis, and data management.

The quality control system includes: an analytical balance, a moisture analyzer, a drying oven, a system for measuring the contact angle of materials (determining hydrophilic/hydrophobic characteristics), and a vacuum system for product preservation.

Main activities:

The MTP laboratory contains an automated system that processes various types of agri-food waste, transforming it through various operational steps into a new resource, revalued for new uses.

The quality control system monitors the characteristics of the waste before, during, and after processing.

The vacuum system allows for the preservation of waste, preserving it for extended periods.

Main equipment:

MTP - Mechanical Treatment Prototype, an automated system for transforming agri-food waste on a laboratory-pilot scale, consisting of:

compressor, purification filters, top-loading waste system with access ladder, drying-grinding-sieving system, collection and weight control system, remote process control system.

Quality control system consisting of oven, scale, moisture analyzer, shredders and small-load sieving system, PC-controlled contact angle meter, vacuum system for bagging/storing samples after treatment.

Contact: avisco@unime.it

Supervisor: prof. Francesco Arena

European Research Council (ERC):

PE4 PE5

Laboratory Location:

Block C, Floor 4, Room 468

Laboratory Type:

Research

Laboratory Brief Description:

Synthesis of Catalytic Materials

Main Activities:

Preparation of Catalytic Materials in Solution and Heat Treatments

Main Instrumentation:

---

Contact: francesco.arena@unime.it

Supervisor: prof. Alessandro Pistone

European Research Council (ERC):

PE4_4 PE5_3 PE5_6 PE5_7 PE5_16

Laboratory Location:

Block C, 4th Floor, Room 469

Laboratory Type:

Research

Laboratory Brief Description:

The laboratory is equipped for sample preparation through liquid- and gas-phase chemical reactions. The laboratory also allows for thermal treatments of solid and liquid samples (e.g., drying in a vacuum oven, with a rotary evaporator, or on an electric hotplate with a magnetic stirrer) and treatments with acids and bases.

Main activities:

Research focuses on the study of advanced synthetic methodologies for the engineering of micro- and nanostructured inorganic, organic, or composite materials for biomedical and environmental applications, such as: synthesis and characterization of biopolymer-polymer matrix coatings for environmental and biomedical applications; synthesis and characterization of ceramic-biopolymer micro- and nano-biocomposites for biomedical applications; synthesis and characterization of organic/inorganic hybrids for tissue engineering and biosensors.

Main instrumentation:

Material synthesis (Horizontal tubular furnace, Autoclave). Sample treatment (Laboratory vacuum oven, Rotary evaporator, Benchtop centrifuge). Morphological characterization (Optical microscope).

Contact: alessandro.pistone@unime.it

Supervisor: prof. Giovanni Neri

European Research Council (ERC):

PE11 PE4_8

Laboratory Location:

Block C, 5th floor, rooms 560 and 564

Laboratory Type:

Research

Laboratory Brief Description:

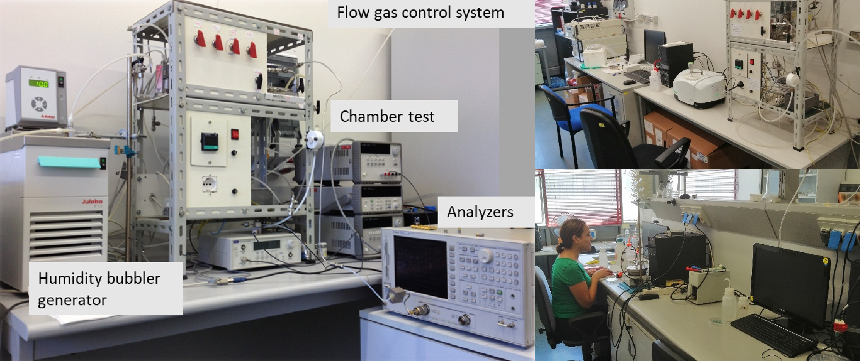

The SensorLab is a cutting-edge laboratory in the field of chemical sensors for advanced applications in the environmental, biomedical, automotive, agri-food, cultural heritage, and energy sectors. SSD CHEM/06.

Main Activities:

The research conducted at the SensorLab covers the many aspects of basic and applied research in the field of chemical sensors.

Main Instrumentation:

Gas sensing setup; setup for electrochemical measurements; setup for electrochemical flow analysis; electro-Raman spectrophotometers, FT-IR and UV-Vis spectrophotometers, electrochemiluminescence analyzer, impedance spectroscopy analyzer. QCM sensors. Setup for measurements with colorimetric and fluorescence sensors.

Contact: gneri@unime.it

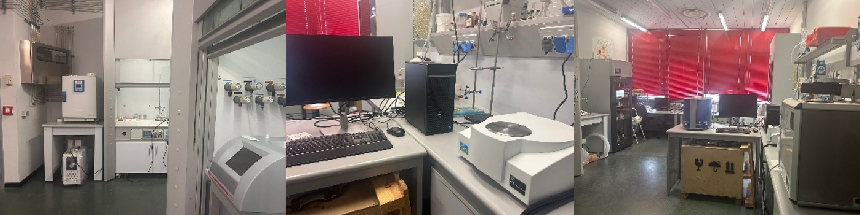

Supervisor: prof.ssa Elpida Piperopoulos

European Research Council (ERC):

PE8_2 PE5_19

Laboratory Location:

Block C, 5th floor, room 561

Laboratory Brief Description:

Research activities in the field of industrial and technological chemistry and materials science (ICHI-02, IMAT-01). The laboratory supports teaching for degree theses and complements other experimental research activities conducted in other laboratories of the department.

Activities:

The laboratory performs thermal and calorimetric characterizations of materials. It is also equipped with an extruder and a spheronizer for pellet production, and offers the possibility of characterizing particles using granulometry and DLS techniques.

Instrumentation list:

Instruments for thermogravimetric characterization (TG – Thermogravimetric Balance, TG STA 449 F3 Jupiter, Netzsch, STA – Simultaneous Thermal Analyzer (TG/DSC), Themis One, Setaram) and calorimetric characterization (DSC – Differential Scanning Calorimeter, DSC 8000, PerkinElmer).

Systems for zeta potential analysis and particle size detection (DLS - Dynamic Light Scattering – Zetasizer Nano Series – Nano ZS, Malvern, Granulometer – Mastersizer 3000, Malvern).

Extruder and Spheronizer: Multi Lab Scientific, Caleva.

Contact: epiperopoulos@unime.it

Supervisor: prof.ssa Daniela Iannazzo

European Research Council (ERC):

PE5_17

Laboratory Location:

Block C, Floor 5, Room 563

Laboratory Type:

Research

Laboratory Brief Description:

The laboratory's activities primarily concern the advanced synthesis and organic functionalization of nanomaterials and biomaterials, with biomedical, sensory, and environmental applications.

Main Activities:

New biomaterials, nanomaterials, and nanocomposites are synthesized and characterized using chemical-physical and thermal techniques, including microwave-assisted synthesis, thermogravimetric analysis (TGA), elemental analysis (CHNS), and nuclear magnetic resonance (NMR). The laboratory offers graduate students, postdoctoral fellows, and undergraduate students research opportunities on nanomaterials and biomaterials, including synthesis, functionalization, and chemical-physical and thermal characterization, for applications in bioengineering and nanotechnology.

Main Instrumentation:

The laboratory is equipped with instruments for the synthesis and functionalization of nanomaterials and biomaterials, including the "Monowave 400" microwave reactor for assisted synthesis, instruments for chemical-physical and thermal characterization, such as a 60 MHz "Spinsolve" benchtop NMR, a "Perkin Elmer TGA 4000" thermogravimetric analysis instrument operating in the 20–100°C temperature range, and an "EMA 502" CHNS elemental analysis instrument. Sample handling equipment is also available, such as a vacuum evaporator and a centrifuge up to 4000 rpm.

Contact: diannazzo@unime.it

Supervisor: prof.ssa Patrizia Primerano

European Research Council (ERC):

PE8_2 PE8_9

Laboratory Location:

Block C, Floor 5, Room 565

Laboratory Type:

Research

Laboratory Brief Description:

The laboratory's activities are aimed at:

testing appropriate technologies for converting waste materials from industrial (biomass, thermoelectric power generation from fuel oil) or civil (post-use glass) activities into higher-value products; and monitoring and controlling process parameters for risk analysis and safety management.

Main Activities:

The waste materials are subjected to hydrothermal treatments with acids and/or alkalis at various temperatures in an open or pressurized reactor and filtered. The resulting liquid and solid phases, as well as the starting materials, are preliminarily analyzed for their chemical composition (liquid phase) and chemical-physical composition (starting materials and solid phase) and subsequently subjected to the following treatments: a) recovery of the metallic (vanadium and nickel) or non-metallic (silica) component from the liquid phase; b) evaluation of the adsorbent performance of the carbonaceous or silicocalcic solid phases resulting from the ash or glass/biomass treatment as a function of various chemical-physical parameters. The monitored processes are analyzed through the application of risk identification techniques and accident consequence simulation models, in order to provide elements to support safety management.

Main instrumentation:

UV/VIS/NIR spectrophotometer, TGA/DSC, high-pressure autoclave, automated potentiometric titrator.

Contact: patrizia.primerano@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE4_4 PE4_16 PE5_3 PE5_4

Laboratory Location:

Block C, Floor 5, Room 566

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory specializes in characterizing the corrosion resistance of materials and evaluating the protective capacity of coatings and surface treatments.

Its use extends to numerous areas of materials science, chemistry, and engineering, for research and third-party services for the study and characterization of surfaces and failure analysis.

The laboratory also houses the Acoustic Emission Section for the study of stress corrosion and brittle fracture mechanisms of materials, for both research and field applications or for third-party services.

Main Activities:

The activities focused on corrosion and material protection are varied and extend from research to field applications.

The laboratory also specializes in studying surfaces, particularly their hydrophobic, oleophobic, and amphiphobic properties.

The laboratory also offers third-party services for material characterization in the field of corrosion and protection of metallic materials according to UNI, ISO, ASTM, and AMPP standards.

Main instrumentation:

AMEL, BioLogic, and PAR Potentiostats/Galvanostats

Contact: edoardo.proverbio@unime.it

Supervisor: prof. Edoardo Proverbio

European Research Council (ERC):

PE11

Laboratory Location:

Block C, Floor 5, Room 567

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory specializes in sample preparation for optical microscopy and optical microscopy observations. Reflection techniques (metallographic investigations) and monofocal or confocal studies are also available.

The laboratory is also equipped to assess the hardness of almost all types of metallic materials, from the softest or thinnest to the hardest, including those with surface treatments.

The laboratory also houses a Leica EM UC6 ultramicrotome, which allows for the simple preparation of semi- and ultra-thin sections of biological and industrial samples for TEM, SEM, AFM, and LM examination.

Main activities:

Preparation and optical observation services for metallic, organic, and organic materials. Metallographic observations for phase identification in metal alloys. Failure analysis of metallic, ceramic, and polymer components (including composites). Material hardness measurement using Vickers, Rockwell B and C, and Brinell techniques. Digital profilometric investigations (optical profilometry).

Main equipment:

Manual and semi-automatic lapping machines. Incorporated equipment for metallographic sample preparation. Leica inverted metallographic microscope. Leica binocular microscope. Hirox confocal microscope - digital profilometer. Leica EM UC6 ultramicrotome.

Contacts: edoardo.proverbio@unime.it

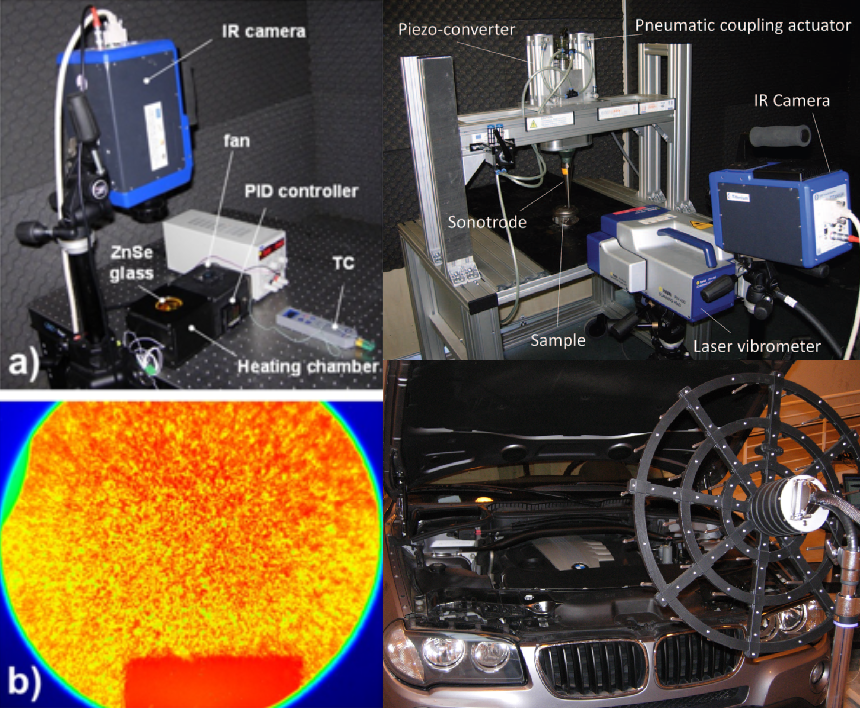

Supervisor: prof. Roberto Montanini

European Research Council (ERC):

PE8_8 PE8_9 PE8_10

Laboratory Location:

Block C, 5th Floor, Room 568

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory develops research and expertise in quality control systems, vibroacoustic comfort analysis, and structural monitoring. The laboratory is active in various research areas, including the development and application of experimental methodologies for non-destructive testing and diagnostics in the industrial, civil, aerospace, nautical, agritech, and biomedical engineering sectors; vibroacoustic analysis for vibration and noise reduction; sensor design and manufacturing; industrial process monitoring and control; and quality control.

Main activities:

Research has a strong applied value, demonstrated by ongoing collaboration with research institutes, private companies, and other universities in Italy and abroad. Main activities and services offered: consulting and commissioned testing for companies and organizations in the fields of non-destructive testing for defect identification, experimental vibration and stress analysis, vibroacoustic monitoring, and structural diagnostics.

Main instrumentation:

Infrared thermal imaging cameras, integrated measurement system for active thermography applications, measurement system for non-contact ultrasonic non-destructive testing, interrogation system for FBG fiber optic sensors, optical spectrum analyzer, NDT using magnetic particle and penetrant analysis, Polytec PSV-400 scanning laser Doppler vibrometer, multi-channel data acquisition system for experimental modal analysis, identification of noise sources using beamforming and acoustic holograms, semi-anechoic chamber, variable-temperature blackbody for calibration of radiometric sensors.

Contact: roberto.montanini@unime.it

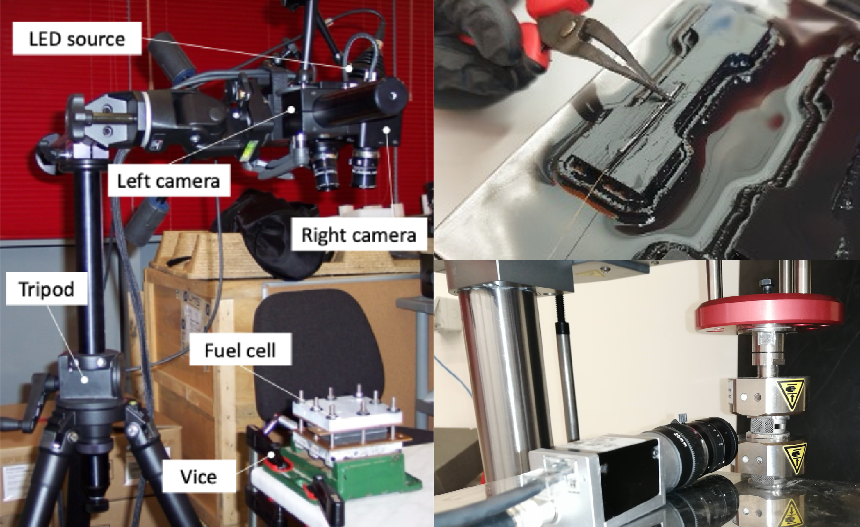

Supervisor: prof. Roberto Montanini

European Research Council (ERC):

PE8_8 PE8_9 PE8_10

Laboratory Location:

Block C, 5th Floor, Room 569

Laboratory Type:

Research and Services

Laboratory Brief Description:

The laboratory develops research and expertise in analysis, design, and testing methods for measuring mechanical and thermal quantities. The laboratory is active in various research areas involving the development and implementation of sensors and measurement systems, experimental stress analysis, and fatigue characterization of materials and components.

Main Activities:

The research activity has strong applied value, demonstrated by ongoing collaboration with research institutes, private companies, and other universities in Italy and abroad. Main activities and services offered: Consulting and commissioned testing for companies and organizations in the fields of mechanical and thermal measurements (force, torque, power, pressure, displacement, position, velocity, acceleration, fluid velocity and flow rate, temperature) and image analysis. Calibration verification services are also available.

Main instrumentation:

Digital Image Correlation instrumentation, contact pressure mapping system, electromechanical testing machine (3 kN), multichannel data acquisition system for strain gauge applications, climatic chamber with controlled humidity generation, a wide range of sensors, cameras, and data acquisition systems, stereolithography 3D printer (Formlabs Form2).

Contact: roberto.montanini@unime.it

Supervisor: prof.ssa Gabriella Epasto

European Research Council (ERC):

PE8_7 PE8_10 PE8_12 PE8_13

Laboratory Location:

Block C, Floor 5, Room 570

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory's activities include non-destructive testing using advanced techniques, such as ultrasound with phased array probes and active thermography with a photovoltaic thermal camera. A thermal camera with a microbolometer sensor is also available for field inspections.

Special expertise has been developed in the testing of lightweight materials (laminates, sandwich panels, light alloy structures) and joints (welding and bonding) for the design of biomechanical, mechanical, and naval structures.

The laboratory's microscopy section allows for surface analysis at medium to very high magnifications using optical, digital, and scanning electron microscopes. 3D surface reconstruction and morphological analysis can be performed using a confocal microscope.

Surface chemical composition analysis can be performed using portable XRF or an EDS probe. Dimensional measurements are also performed on porous structures created using additive manufacturing.

Structural analyses using FEA with explicit (high strain) and implicit (linear elastic field) codes.

The expertise covers Mechanical Design and Machine Construction (IIND-03/A) and Naval Construction and Systems (IIND-01/B).

Main activities:

Failure analysis of a structure or mechanical component. Non-destructive testing of welds. Non-destructive surface analysis. Non-destructive testing of composite materials and lightweight structures. Non-destructive analysis of porous and lattice structures. Structural defect analysis, including in situ investigations. Composition analysis of alloys, soils, and precious metals. Detection of structural damage due to mechanical loads on joints and lightweight structures. Structural analysis using the Finite Element Method.

Main equipment:

Optical stereomicroscope (Leica M165C). Metallographic microscope (Leica DMi5000). Portable digital microscope (Leica DVM 5000). Confocal microscope (Leica DCM3D). Benchtop SEM with EDS probe (Hitachi TM3030plus). MW IR thermal imaging camera with cooled detector (Flir Systems). X8400sc) Portable LW IR thermal imaging camera with microbolometer detector (Flir Systems SC640) Pulsed and lock-in thermography system Portable XRF system (Ametek SPECTRO xSORT) Phased Array ultrasound (Olympus Focus PX with 5 MHz and 3.5 MHz NW probes, VersaMOUSE, and tube encoder) Workstation for implicit and explicit FE analysis

Contacts: gabriella.epasto@unime.it

Supervisor: prof.ssa Francesca Garescì

European Research Council (ERC):

PE7_5 PE7_10 PE8_7

Laboratory Location:

Block C, Floor 5, Room 571

Laboratory Type:

Research and Teaching

Laboratory Brief Description:

Non-destructive analysis with piezoelectric and laser vibrometers on micro- and macromechanical systems, particularly temperature-dependent vibration measurements on microelectronic boards. Research and teaching activities with a serial robot arm for pick-and-place operations. Areas involved: IIND-02/A, IIET-01/A, PHYS-03/A

Main activities:

--

Main instrumentation:

Polytec micro system analyzer 500 (MSA-500) scanning vibrometer

FANUC LR Mate 200iD 4S serial robot with FANUC SYSTEM R-30iB Mate controller

Contact: francesca.garesci@unime.it

Supervisor: prof. Antonio Galvagno

European Research Council (ERC):

PE8_5 PE8_6

Laboratory Location:

Block C, Floor 5, Room 572

Laboratory Type:

Research, Teaching, and Services

Laboratory Brief Description:

The laboratory is equipped to conduct research on conventional and innovative energy systems from renewable energy sources (wind, photovoltaic, solar thermal, etc.). Experimental studies are conducted on free-flow and ducted aeraulic systems (horizontal/vertical axis) for the recovery of wind and wave energy. Furthermore, particular attention is paid to the integration of CHP/trigeneration systems with systems for the conversion of production waste (mash, pomace, grape marc, etc.) into solid, liquid, and gaseous fuels used to power conventional and CHP-based MCIs, gas turbines, and fuel cells.

Activities:

Fluid dynamic characterization of fluid machine rotors

Monophasic and two-phase flow analysis

OWC system analysis

Fuel injector characterization

Spray analysis

Industrial waste characterization

Biomass gasification

Energy analysis of systems for the production of fuels (solid, liquid, and gaseous) from industrial waste

Energy and material balance analysis on CHP systems

Main instrumentation:

Fluid velocity measurement system (Particle Image Velocimetry):

2D-PIV, stereo-PIV, and tomo-PIV

Double-pulsed Nd:YAG laser

2 CCD camera

High-speed imaging system, maximum resolution 1280x800 pixels, maximum fps 1077,500 @ 128x16 pixels;

System for measuring the calorific value of fuels;

Software:

AVL CRUISE™ M, AVEVA PRO/II Simulation – The Trusted Steady-State Process Simulator

Contacts: antonio.galvagno@unime.it

Supervisor: prof. Antonio Piccolo

European Research Council (ERC):

PE8_3 PE8_4 PE8_5 PE8_6

Laboratory Location:

Block C, 5th Floor, Room 573

Laboratory Type:

Research

Laboratory Brief Description:

The Technical Physics Laboratory conducts various design and experimental research activities in the typical fields of Environmental Technical Physics and Industrial Technical Physics. This research focuses primarily on energy (study of renewable and sustainable energy sources; efficiency of heating and cooling machines), environmental comfort control in confined and outdoor spaces (thermohygrometric, acoustic, and lighting), and the thermophysical properties of advanced building materials/components for energy savings (innovative glass surfaces, PCM).

Main activities:

Design and prototyping of electric generators and refrigeration units based on thermoacoustic technology; development of simulation codes for the thermal behavior of thermoacoustic components; theoretical/experimental study of innovative glass surfaces using climatic test cells; measurement and monitoring of thermohygrometric, acoustic, and lighting environmental parameters to define indoor environmental comfort; environmental noise measurements and validation of forecasting models; design, simulation, and thermodynamic and environmental analysis of biomass systems for the production of electricity, heat, and biohydrogen; study of materials, systems, and equipment for the production and use of renewable energy; equipment for measuring environmental parameters to define thermohygrometric comfort conditions;

Main instrumentation:

Equipment for measuring energy flows in thermoacoustic devices; climatic test cell for studying the thermophysical behavior of advanced materials for reducing energy consumption in buildings; process simulation software.

Contacts: apiccolo@unime.it